Want to Save 30% off Any Shed Plan Purchase!

Signup For My 'Shed n Sight' Newsletter

and Get Your 30% off Promo Code To Use At Checkout.

- Home

- Shed Construction

Useful Shed Construction Information For You

Here are some helpful Shed construction items that will help you in your shed building process. The links listed below are grouped into each building phase and should be helpful for you in building your new shed, playhouse, small cabin, chicken coop, tiny house, etc.

Shed Floor Construction

Shed Wall Construction

Shed Door Construction

Shed Roof Construction

Shed Styles and Designs

A gambrel of barn style shed roof is one of the most popular and common shed styles to build. They offer the most storage space for a shed because the loft area is much larger just due to the size of the roof framing. Check out these barn style plans.

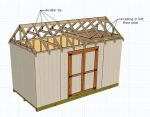

A gable style shed is perhaps one of the easiest styles of sheds to build. The roof can be built using a ridge board, or with trusses. Most of my gable plans show roof construction using pre-built trusses. Here's some more information on gable shed roofs and how to build them.

Lean to shed sheds have what is commonly known as a 'shed roof'. The roof on a lean to shed has just one slope, front to back or back to front. Here's some lean to plans I have for sale on my site.

Saltbox style sheds have 2 roof slopes. The front roof slope is usually greater in pitch and the rear is less of a pitch. This typically is due to the front wall being taller than the rear wall. You can see examples of saltbox sheds here on my site. My saltbox sheds have the same heigth front and rear walls, however the front and rear roof pitches are different.

Here's a few more terms used in shed construction

Footer

A footer refers to the concrete foundation under a concrete floor and typically is around the perimeter of the slab. It can be anywhere from 4" deep to over 36" deep depending on the local freeze depth. Footers are thicker for the purpose of supporting exterior wall structures.

Wall Framing

Framing refers to the assembly of wooden shed floors, walls, and roof. For example, if one is framing shed walls, he/she is assembling together by nailing or using screws the bottom or sole plate, top wall plate, and wall studs.

Galvanized

The term 'galvanized' from the Merriam-Webster dictionary:

Coated with zinc to prevent rust.

With shed floor construction I typically use galvanized nails to nail the floor framing together just due to the fact that the moisture content around a shed floor is high and galvanized nails do not rust because of their being coated with zinc. And anywhere else that the shed may be exposed to moisture I will use galvanized nails. Another good example would be a shed ramp, shed doors, and shed floors, and corner trim or any other exposed trim on a shed.

O.C. or On Center Framing

When you are framing wooden shed floors, walls and the roof, o.c. refers to the on center positions that the middle of a floor joists, wall stud, rafter, or roof truss fall on. For example if your floor joists are spaced 16" o.c. this means that the middle of each floor joist will be exactly at 16". So if you measure at 16" from the end of your floor framing, the first interior joist location will be centered at 16", and the second at 32" o.c., the third at 48" o.c., the fourth at 64" o.c. and so on.

OSB

The following is taken from the website: https://www.apawood.org/osb

Oriented Strand Board is a widely used, versatile structural wood panel. Manufactured from waterproof heat-cured adhesives and rectangularly shaped wood strands that are arranged in cross-oriented layers, OSB is an engineered wood panel that shares many of the strength and performance characteristics of plywood. OSB's combination of wood and adhesives creates a strong, dimensionally stable panel that resists deflection, delamination, and warping; likewise, panels resist racking and shape distortion when subjected to demanding wind and seismic conditions. Relative to their strength, OSB panels are light in weight and easy to handle and install.

Rim Joist

When building a shed floor, a rim joist is the outer most joist on either end.

Shingles

Shingles are a type of building material used for roofing or siding. They are typically flat and rectangular, overlapping each other on the roof or walls of a building to keep out rain, snow, and other elements. Shingles can be made from a variety of materials, including asphalt, wood, metal, plastic, slate, and composite materials. The choice of shingles can greatly affect the aesthetic and durability of a building's exterior.

Siding

Siding is the exterior covering or cladding of a house or other building meant to shed water and protect the structure from the effects of weather. In addition to serving a functional role, siding also often determines the appearance or aesthetic of a house.

Several types of siding can be used in building a shed, each with its own benefits and considerations:

1. Vinyl Siding: This is the most commonly used type of siding due to its affordability and durability. It is resistant to moisture, insects, and harsh weather conditions. Vinyl siding comes in many styles and colors.

2. Wood Siding: Wood siding offers a classic and beautiful look. It can be stained or painted any color. Common types of wood used are cedar, pine, spruce, and redwood. However, wood siding requires regular maintenance to prevent rot, insects, and weather damage.

3. Metal Siding: Often made of aluminum or steel, metal siding is durable and requires little maintenance. It is resistant to fire and pests. It can also be painted in any color to suit your design preferences.

4. Fiber Cement Siding: This type of siding is made from a blend of cement, sand, and wood fibers. It is exceptionally durable and can mimic the look of wood, stucco, or masonry. It's resistant to termites, rot, and fire.

5. Brick or Stone Siding: Made from natural resources, these types of siding are some of the most durable. They offer a timeless look and require very little maintenance once installed. However, they can be more expensive and difficult to install.

6. Engineered Wood Siding: This is a stronger and more durable alternative to traditional wood. It's made of wood fibers bonded with a resin under heat and pressure.

7. Stucco: Mostly used in the southwestern United States, stucco is a cement-type mixture added to sand or lime. It's durable and gives a unique southwestern appearance to the building.

When building a shed, it's crucial to consider the climate, your budget, and the desired aesthetic when choosing a type of siding.

What is a wall 'stud'?

A wall stud is a vertical framing member in a building's wall structure. They are typically made from wood or metal and are part of the framework that helps to give the wall its shape and provide a surface to which interior or exterior wall coverings can be attached. Wall studs are also crucial for supporting any additional wall elements like windows, doors, or cabinetry. Generally, wall studs are evenly spaced out, usually 16 or 24 inches apart from the center of one stud to the center of the next.

What does 'toe-nail' mean?

"Toe-nailing" wood refers to the process of driving a nail at an angle through a piece of wood into another piece. It's a useful technique when seeking to fasten two pieces of wood together, typically at a right angle. This method provides strong support and can be useful in situations where you cannot drive a nail straight through one piece of wood into another. To achieve a successful toe nail, you angle the nail so it goes through the edge of one piece and into the other, creating a sturdy joint.

Top plate

The term 'top plate' in shed construction refers to the horizontal framing member that sits on top of the wall studs. It provides stability to the overall wall structure and forms a secure base for fastening the roof or additional stories. In most constructions, a 'double top plate' is used, where two boards are laid horizontally on top of the studs, one on top of the other, providing extra strength and stability.

Treated lumber

In shed construction, treated is referred to when using pressure treated lumber. I often include pressure treated lumber in my shed plans for the floor framing because it withstands the weather elements better than if you were to just frame your floor with regular untreated lumber.

Trim

In terms of shed construction, 'trim' refers to the finishing pieces used to cover transitions between surfaces or for decoration. It's often used around windows, doors, and the corners of the shed. Trim serves both an aesthetic and functional purpose. Aesthetically, it can provide a polished, finished look to the shed's exterior. Functionally, trim helps seal the shed from weather and pests by covering seams where different materials meet. The types of trim can vary, but it's usually made from material like wood, metal, or plastic.

'Z' Strip weather flashing

Protect the horizontal edges of your shed siding with Z Flashing

Here's some more information on related shed building you may be interested in.

Monthly DIY

Shed-in-sight

Newsletter

Subscribing will get you discounts on shed plans, monthly updates, new shed design ideas, tips, exclusive discounts on shed building resources and tools. Learn more here.

Recent Articles

-

Does Your Shed Need Shed Floor Skids?

Feb 12, 25 05:53 AM

Shed floor skids will help support your shed floor. They will also allow you to anchor your shed floor to the ground using concrete piers. See how here. -

Gusset fasteners

Feb 06, 25 06:31 AM

For fastening gussets to shed trusses, is it best to use nails or bolts? -

Easy Diy Shed Plans and Ideas For You To Build Sheds

Dec 31, 24 09:49 PM

All types of shed plans for gable, barn, saltbox, and lean to style sheds small and large that can be used for storage, shed to house, workshops and more.

My You Tube Videos